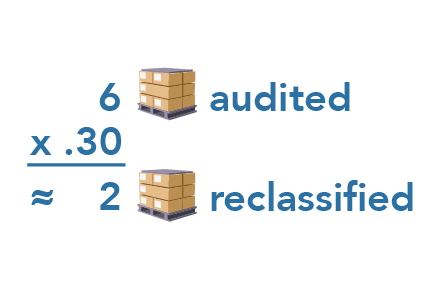

In 2022, the average carrier audits 60% OR MORE of the freight that comes through its doors. For example, if you ship 10 pallets a day, your carrier likely uses a pallet dimensioner to audit the dimensions and weight of 6 of those pallets. That number will continue to climb as carriers aim to increase the percentage of pallets they audit with a goal of around 90%.

On average, 25-30% of the audited freight gets reclassified based on the carriers’ findings. The data from their pallet dimensioners show that your declared measurements and dimensional weight were inaccurate. Of the 10 pallets you shipped, 2 were flagged and were reclassified.

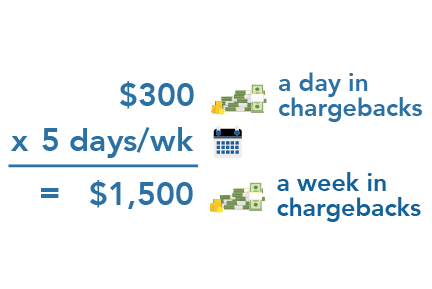

Carrier chargebacks typically range between $50-$250 per pallet. In this scenario, we’ll use $150 as the average penalty assessed to a reclassified pallet. 2 reclassified pallets at $150 per pallet equals $300 a day in unnecessary chargebacks.

$300 a day in chargebacks is a hard pill to swallow, especially when those penalties are avoidable. Add that up over a typical five-day work week and you’re looking at $1,500 per week in carrier chargebacks.

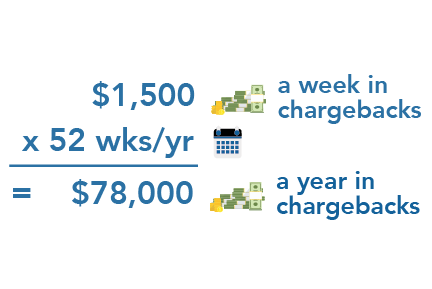

Over the course of a year, your manual measurement process could cost you close to $80,000! That’s significant capital that could be allocated to other parts of the business.

If the above numbers are a close representation of your shipping volume, you’re looking at an ROI of less than 6 months on a pallet dimensioning system. If you ship more than that, you’ll realize that ROI even faster.

Introducing pallet dimensioning into your shipping operation is an investment in the health and future of your company. Make that investment today and you’ll start to see immediate returns.