Contour data goes beyond standard dimensions. With a contour system, you can gain a complete picture of your pallet, and the products stacked on it—a crucial advantage in optimizing your palletizing process. In this article, we’ll explore key signs your facility may need more detailed load data and the operational benefits that enhanced contour data can deliver.

Indicators That You Need Contour Data

Some warehouse operations are more primed than others for implementing a contour dimensioning system. If any of the following scenarios apply to your facility, it’s time to consider upgrading your palletizing workflow with contour data:

- Your operation uses specific pallet recipes (standardized composition of each load).

- Your facility relies on measurement data for tight-space put-away.

- You use AGVs (Automated Guided Vehicles) for pallet handling and placement.

- Your warehouse faces frequent QA issues like damaged, missing, or poorly loaded products.

The Benefits of Contour Data in Palletizing

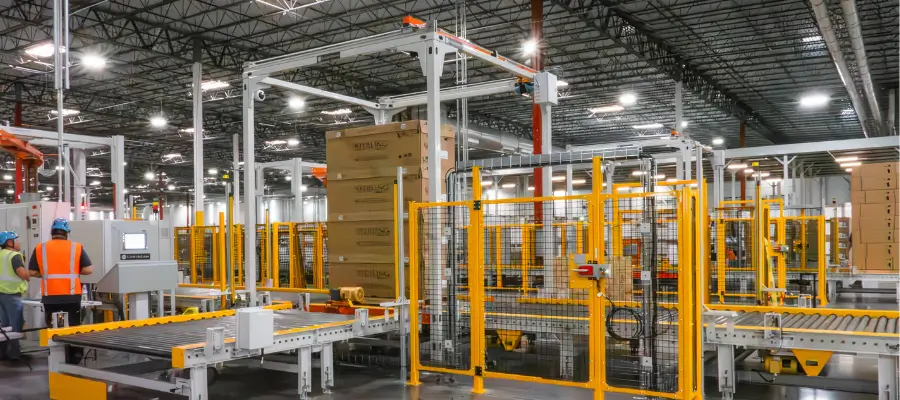

Contour systems provide clean, trusted data that can be used by both robotics and human operators to improve load accuracy, efficiency, and safety. But the value of this technology extends beyond just data capture. It plays a pivotal role in protecting your product, your people, and your bottom line.

Product Protection

According to recent industry data, 34% of product returns stem from damage. The true cost of those returns isn’t limited to product replacement—it includes chargebacks, packaging waste, and higher transportation costs. These losses quickly accumulate when shipping thousands of pallets per day.

Contour data helps validate each pallet’s structure by referencing a pre-established load recipe—the ideal size, shape, and stacking arrangement of a palletized load. Loads that don’t meet these standards can be rerouted to a rework area, reducing the risk of AGVs mishandling unstable pallets and damaging freight during the palletizing or shipping process.

Worker Safety

Workplace accidents remain a costly concern. In 2020, the total cost of medically consulted injuries in the U.S. was $163.9 billion. With contour technology, you can proactively mitigate risk.

A contour dimensioning system inspects pallet structure and content conditions. If a load fails to meet pass/fail parameters, it won’t be handled by AGVs—it will instead be redirected for inspection or repalletizing. This reduces the risk of collapsed pallets that could injure employees, providing a significant safety benefit in any palletizing environment.

Profit Protection

Reducing product damage and workplace injuries ultimately protects your profitability. But contour systems also increase operational efficiency. By feeding reliable data into your warehouse automation or WMS, you streamline decision-making for slotting, picking, load building, and palletizing. The result? Better throughput, lower costs, and a smoother supply chain.

Elevate Your Palletizing Process with Contour Data

Too often, businesses invest in innovation after a costly failure. Contour dimensioning gives you a way to prevent problems before they occur. By adopting the Cubiscan Contour Pro, your operation can capture the data needed to improve every aspect of your palletizing process—from safety and accuracy to efficiency and ROI.

To learn more about the Cubiscan Contour Pro and other palletizing dimensioners, click the button below, or contact our team by emailing info@cubiscan.com or calling 801.451.7000

About Cubiscan

For over 30 years, Cubiscan has led the automated dimensioning industry. In the 1980s, it became clear that accurate dimensions and weight were essential for warehousing, distribution, right-size packaging, and freight-manifesting applications. By the mid-1990s, the company had established itself as an innovative supplier of static and in-motion dimensioning systems. Today, Cubiscan continues to innovate and guide its customers to effective material handling solutions by offering the broadest range of dimension-scanning technology available.

Cubiscan Media Contact: Aaron Taylor, Marketing Director – ataylor@cubiscan.com